DWC Aeration Manifold Design That Actually Works: Uniform DO Without Wasting Power

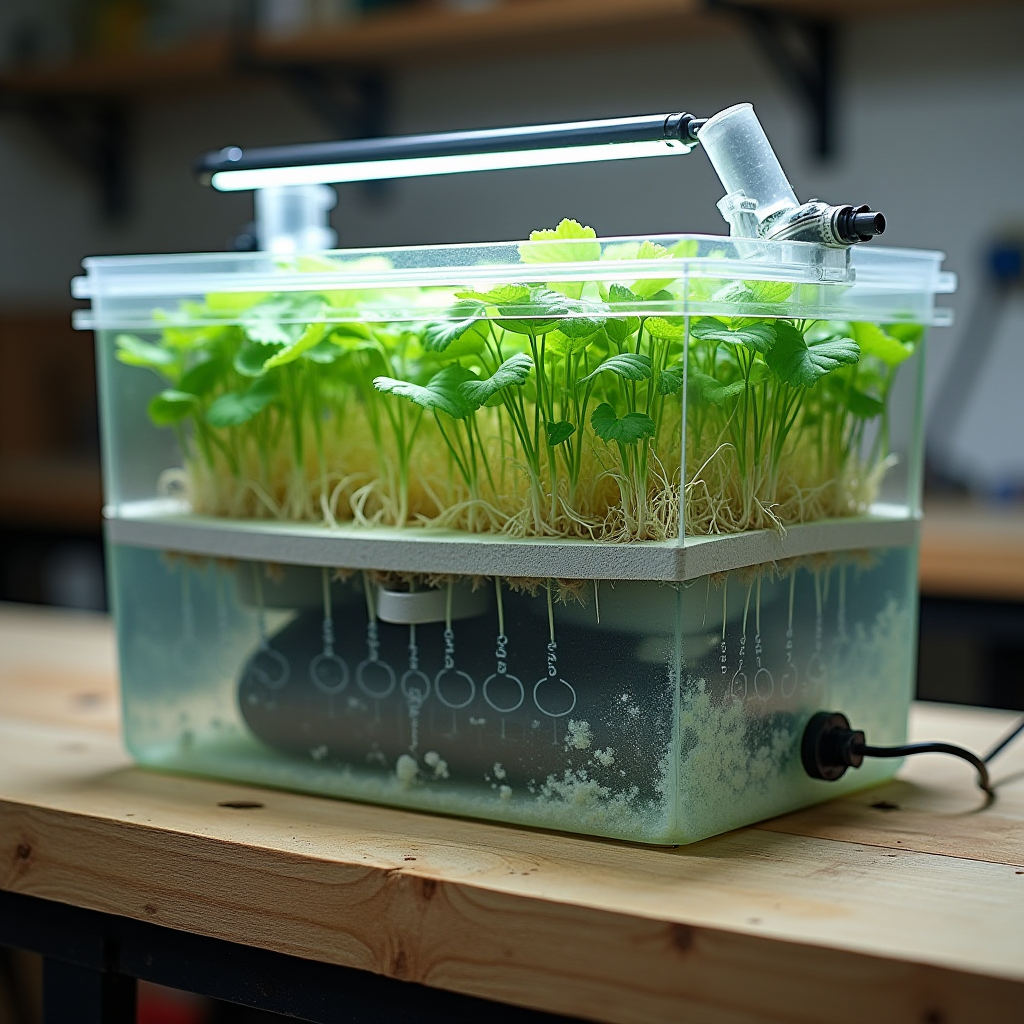

“Just add more airstones” is some of the most expensive bad advice in DWC. Oversized pumps, random tee fittings, and a handful of stones will give you bubbles, but not necessarily oxygen where roots actually need it.

In big raft beds and school or office systems, that gap shows up as classic “mystery failures”: one corner of the bed stunts, one row gets pythium first, one channel always runs hotter in summer. On paper the system has “plenty of aeration”. In reality, the aeration manifold is doing you dirty.

This article is about fixing that at the design level: how to lay out manifolds (loop vs branch), size lines, choose between airstones and microbubble diffusers, when to use venturi injection, and how to validate that DO is uniform instead of guessing.

1. Common Mistakes In DWC Aeration Manifold Design

1.1 Treating “more bubbles” as the only goal

Most plug-and-play raft systems rely on a single large pump pushing air to a random collection of stones. You see a storm of bubbles near the manifold and almost nothing at the far end of the bed. That looks impressive from the surface, but you can still have low dissolved oxygen (DO) at root depth.

DO, not bubble density, is what keeps roots alive. As outlined in DWC overviews, roots in deep water culture rely on a continuously oxygenated solution to avoid hypoxia and root rot.

1.2 Linear branch manifolds with pressure loss at the tail

The standard “one long line with tees” layout is the biggest culprit in raft beds and multi-bucket DWC. Air exits at the first few outlets, pressure drops, and the last stones barely breathe. The pump works hard, but the layout guarantees uneven output.

1.3 Mismatched tubing, fittings, and stones

Mixing 3 mm, 4 mm, and 6 mm ID tubing on the same line, plus using different airstone types (fine, medium, cheap porous blocks) sends backpressure all over the place. Air takes the path of least resistance, so the lowest-backpressure stones hog the flow.

1.4 No valves, no balancing, no measurement

A lot of school and community systems are set up for “low maintenance”, which usually means no mapped DO readings at all, just an occasional look at bubble activity. Yet DO is straightforward to measure using electrochemical or optical probes, and it is widely recognized as a critical parameter in DWC management.

Without at least basic DO spot checks and simple airflow balancing valves, you are flying blind.

1.5 Ignoring water circulation and venturi options

Where systems already run a recirculation pump (common in recirculating DWC and raft raceways), many growers still treat aeration as a totally separate subsystem. They miss the chance to integrate venturi injectors or inline oxygenation into that pumped loop, which can add a lot of oxygen with the power you are already spending on water flow.

2. Why These Mistakes Happen (And How Air Really Moves)

2.1 Manifolds behave like plumbing, not magic

Air behaves like water in a manifold: pressure drops along the run, and every restriction (small ID tubing, tight elbows, high-backpressure stones) steals pressure from everything downstream. In a straight branch layout, that means outlets near the pump always outperform outlets at the end.

Commercial raft systems that succeeded at scale, such as the raceway-style DWC developed by Jensen and others, intentionally built in distributed aeration and flow patterns to avoid dead zones. Hobby and school setups often skip this engineering step and just “hang stones off a pump”.

2.2 Confusing bubble appearance with oxygen transfer

Airstones that throw big, coarse bubbles look dramatic. But coarse bubbles have very little surface area per unit volume and rise fast, which means relatively low oxygen transfer per watt. Microbubble diffusers, by contrast, produce very fine bubbles with far more surface area. That increases the contact time with water and raises DO more efficiently.

When you chase “visual foam” instead of measured DO, you end up oversizing pumps to compensate for inefficient diffusers.

2.3 Set-and-forget in public and community installations

In places like school dining halls and community hubs where hydroponic installs are used as education tools, the priority is usually plug-and-play reliability and low maintenance. Northfield Mount Hermon School’s recent installation is a great example of a highly visible, educational system where daily tech work is not the goal. Affordable DO meters, or even a periodic DO mapping routine, often never make it into the spec.

In community food projects, like the Acres Homes hydroponics program in Houston, the push is to get systems running and feeding people fast. Aeration layout and sensor mapping can feel like a “luxury” problem, right until a warm week and a clogged stone wipe out a bed.

2.4 Underestimating how quickly DWC can crash

DWC is forgiving until it is not. Roots can tolerate marginal DO for a while, then an uptick in temperature, plant biomass, or organic load suddenly pushes demand past supply. That is why simple DIY DWC guides stress constant aeration as non-negotiable. If your manifold has hidden weak points, you usually discover them at the worst possible time.

3. How To Fix It: An Aeration Manifold Pattern That Actually Works

3.1 Design the manifold as a loop, not a dead-end branch

The single biggest improvement you can make is to run your main air header as a closed loop around the system instead of a straight line. This equalizes pressure because every outlet has two paths back to the pump.

- For raft beds: Run a rigid or semi-rigid ring (PVC, polyethylene) around the perimeter of the tank, or a rectangle that tracks the raft edges. Tap drop lines down to your stones or diffusers under each zone.

- For multi-bucket DWC: Run a loop across all buckets, circling back to the pump. Each bucket gets one or more drop lines with valves.

This simple loop topology immediately reduces the “first outlet hogs the air” problem that plagues straight manifolds.

3.2 Keep line sizes consistent and appropriately large

- Use a main header that is at least one size larger than your drops.

- Avoid sudden neck-downs. If your pump outlet is 10 mm, do not immediately pinch it into a long run of 4 mm airline.

- Use smooth bends wherever possible to reduce friction losses.

This keeps backpressure predictable and helps your balancing valves work as intended.

3.3 Use a valve on every drop

Install a small inline valve on each drop line to each diffuser. That way, when you perform DO mapping (more on that below), you can deliberately throttle over-performing zones and push more air to weak spots.

Skip the “octopus manifold” blocks with fixed outlets and no valves. They look tidy but remove your ability to tune the system.

3.4 Match diffuser types and backpressure

In any one reservoir, pick a single diffuser type and pore size. Mixing cheap high-flow stones with high backpressure microbubble discs on the same loop will always bias flow to the low-resistance devices.

As explained in general guides to bubble stones, finer diffusers increase backpressure but also increase oxygen transfer thanks to higher surface area. When you standardize on one type, every drop sees similar resistance and your manifold behaves predictably.

3.5 When to choose airstones vs microbubble diffusers

- Conventional airstones are fine for small DWC buckets, hobby systems, and short raft beds. They are cheap, easy to replace, and work well if you design the manifold correctly.

- Microbubble diffusers shine in large raft systems, warm climates, and high-density plantings where DO demand is high. They can hit target DO levels at lower airflow, which lets you run smaller pumps for the same oxygenation.

If you are running a big shared reservoir for a classroom or community kitchen, leaning toward microbubble discs plus a looped manifold is usually worth the extra cost in hardware and setup time.

3.6 When to add venturi oxygenation

If you already run a recirculation pump (RDWC, raceway or raft with turnover), a venturi injector in the return line lets you use water flow to pull in air and create fine bubbles.

- Size the venturi to the pump’s flow range.

- Install it on the pressure side of the pump with a short suction line exposed to air.

- Add a ball valve or bypass loop so you can tune flow and avoid cavitation.

Venturi injection will not always replace all airstones, but it can dramatically lift baseline DO while reducing how hard your air pump has to work.

4. What To Watch Long-Term: Verifying Uniform DO The Smart Way

4.1 DO sensor mapping for real uniformity

Uniform dissolved oxygen in hydroponic raft systems is not a guess; you can map it. A basic protocol looks like this:

- Get a DO meter (optical probes are easier to maintain than galvanic, but either beats guessing).

- Define sample points: corners, center, and a few spots under dense planting zones. In deeper tanks, include surface, mid-depth, and near the bottom.

- Record DO and temperature at each point with the system in normal operation.

- Adjust valves on your aeration drops in small steps, then remap.

The goal is to get DO within a tight band (for example, 6.5–8.0 mg/L) across all points, while keeping temperature in a safe range. Research on DWC control systems emphasizes the importance of stable solution conditions for consistent plant performance.

4.2 ATP swabs and root-zone hygiene

DO meters tell you how much oxygen is available. ATP hygiene swabs (or periodic root inspections) tell you how biology is using it.

- If ATP counts or slime buildup are always high in one region of a raft or in one DWC bucket, you probably have a local aeration or flow issue.

- Combine DO mapping with root checks. Brown, mushy roots plus marginal DO in the same location is your smoking gun.

4.3 Integrating DO with your nutrient and pH routine

Most DWC growers already watch pH and EC like hawks. Adding DO checks to that routine gives you a far clearer picture of system health. DWC guides consistently highlight pH 5.5–6.5 as a sweet spot for nutrient availability, and that same range works well for oxygen solubility under normal temps. Track all three together:

- If DO drops while EC and pH are stable, suspect aeration layout, biofilm, or temperature.

- If DO and pH both drift (especially upward), look at low circulation and photosynthetic activity from algae in the reservoir.

4.4 Seasonal and biomass adjustments

Schools, offices, and community hubs tend to run predictable planting cycles: salad bars in winter, heavier-fruiting crops in warm months. Oxygen demand tracks plant biomass and water temperature, so aeration needs change over time.

- Plan to redo DO mapping when the canopy doubles in size or when room temps shift by more than 3–4 °C.

- Keep one or two unused drops in your looped manifold so you can add extra diffusers in hot spells without redesigning the system.

4.5 Where passive systems fit in (Kratky vs DWC)

The Kratky method stays competitive for small, low-tech installs because it offloads oxygen supply to the air gap above the solution instead of mechanical aeration. For desktops, windowsills, and tiny classroom experiments, that is great. But once you move into shared raft beds, classroom salad production, or community-scale leafy greens, DWC and raft systems with engineered aeration will always give more stable yields.

So, use Kratky where you genuinely want zero moving parts. For everything else, treat the aeration manifold as critical infrastructure, not an afterthought.

As an Amazon Associate, I earn from qualifying purchases.