Sea‑Freight Hydroponic Herbs & Baby Leaf from South Africa to Singapore: MAP/CA Settings, SFA Compliance, and Cold‑Chain SOP

“You can’t ship basil by sea.” That line still gets thrown around at hydroponic conferences. It was true when people packed herbs like lettuce, ran reefers at a single setpoint, and hoped for the best. Today, with the right MAP film, CA profile, and cold‑chain discipline, 10–14‑day sea‑freight from South Africa to Singapore is not just possible – it’s repeatable.

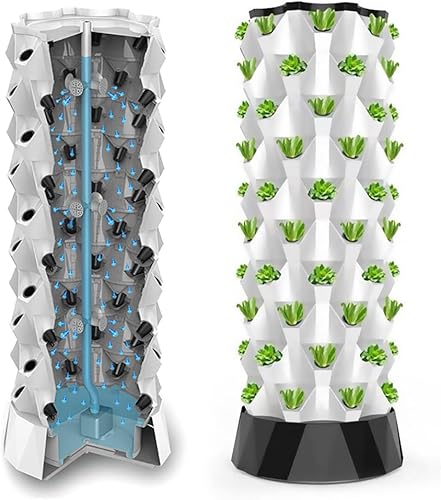

This playbook is written for hydroponic growers running serious systems (NFT, DWC, high‑density raft, even container farms) who want to convert Singapore’s new demand signal into stable, low‑claim export programs – not one‑off “lucky” shipments.

We’ll stay practical: viable SKUs, transit limits, MAP and CA setpoints, humidity and pre‑cooling, plus the paperwork and pesticide rules that will make or break you at SFA inspection.

1. Common mistakes when exporting hydroponic herbs & baby leaf by sea

1.1 Treating all herbs like lettuce (or like each other)

Hydroponic lettuce is forgiving at 0–1 °C. Many herbs are not. Basil is chilling‑injury sensitive below about 10 °C, while parsley, coriander, chives and most baby leaf lines prefer 0–2 °C. Mixing them in the same reefer with one generic setpoint is the fastest way to arrive with blackened basil and limp leaves.

1.2 Guessing at MAP and CA instead of matching respiration

Another common failure: “MAP by catalog” – picking a random herb film or generic salad bag and trusting the marketing copy. High‑respiration herbs (basil, coriander) and dense baby leaf mixes chew through oxygen fast. If O2 crashes below about 1–2 %, you swing to anaerobic off‑odors and slime. If OTR is too high, you lose the benefit of MAP and arrive yellow and dehydrated.

1.3 Weak pre‑cooling and patchy cold‑chain handover

Hydroponic product starts colder and cleaner than soil‑grown, but it is still perishable. Many exporters:

- Pack warm product straight out of the greenhouse.

- Slow‑cool pallets in ambient loading bays.

- Let containers sit unpowered during truck transfers.

PPECB is very clear: time to pulldown and uninterrupted cold‑chain are non‑negotiable for export vegetables, and they audit these steps on site as part of South Africa’s export control regime through their standards.

1.4 Underestimating Singapore’s SFA and MRL expectations

Singapore has made it explicit that food security rests on diversified, reliable import sources, and has singled out South Africa as a trusted partner in its diversification push as reported by CNA. That reliability includes food safety.

Hydroponic growers often assume “we use less pesticides, so we’re safe”. That’s a claim‑generation mindset. SFA enforces specific Maximum Residue Limits (MRLs) for pesticides across vegetables and herbs and will hold consignments or require recalls if limits are breached, as outlined in their pesticide residue guidance.

1.5 Treating documentation as an afterthought

Last big mistake: tidying labels and certificates the night before container closing. For fresh produce, the documentation stack is part of the product:

- PPECB export inspection and certification.

- DALLRD (South Africa’s agriculture department) phytosanitary certificate.

- SFA importer license and permit on the Singapore side, plus correct product classification and country of origin declaration as detailed here.

Any weak link here can hold or destroy a container that was perfect inside.

2. Why these mistakes happen (and which SKUs actually work)

2.1 Not all hydroponic herbs are sea‑freight material

Before arguing over OTR and CA, decide what you should ship at all. For a 10–14‑day sea lane South Africa → Singapore, plus harvest and distribution time, think in terms of physiological shelf life at the correct temperature and atmosphere.

Generally viable for 10–14‑day sea‑freight with MAP and CA:

- Parsley (flat and curly): High tolerance to 0–2 °C, moderate respiration.

- Coriander (cilantro): High respiration but manageable with tight cold‑chain, high‑OTR film, and CO2 moderation.

- Chives, spring onions, dill: Similar to leafy veg; respond well to low temperature and moderate humidity.

- Robust baby leaf mixes: Rocket, spinach, Asian greens, mustard, tatsoi, kale blends when harvested young.

High‑risk or marginal for 10–14‑day sea‑freight:

- Basil: Chilling injury below ~10 °C; blackening and rapid quality loss at small temperature excursions. Suitable only with warm setpoint (10–12 °C), excellent MAP design, and strict segregation from cold‑tolerant herbs. Many exporters still use air freight for basil for this reason.

- Very delicate microgreens, red‑pigmented baby leaves: Damage easily under pressure and CO2; better for air‑freight or ultra‑short sea routes.

Hydroponic systems like NFT and DWC can produce very consistent, clean leaves, which is exactly what containerised export operations in South Africa have been building towards, as highlighted in case studies of high‑tech farms in the region such as this Grozine feature. But physiology still wins over system design: choose SKUs that give you a biological buffer.

2.2 Misunderstanding temperature bands and CA for different herbs

Sea‑freight containers with CA are powerful, but they are blunt instruments if you do not respect species differences.

Cold‑tolerant herbs & baby leaf (parsley, coriander, chives, baby leaf mixes):

- Typical reefer setpoint: 0–2 °C.

- Target O2 in CA: 2–5 % to slow respiration without pushing anaerobic stress.

- Target CO2 in CA: 3–8 % depending on mix and sensitivity to CO2 burn.

Warm‑sensitive basil:

- Typical reefer setpoint: 10–12 °C to avoid chilling injury.

- Target O2 in CA: often slightly higher, around 5–10 %, to avoid fermentation.

- Target CO2 in CA: usually limited to 3–5 % to avoid leaf spotting.

When shippers mix products to “save” on reefer costs, they end up picking a compromise setpoint that suits nobody. That is how a technically correct CA profile still delivers poor quality.

2.3 MAP mistakes: wrong OTR, wrong pack geometry, wrong pre‑cooling

MAP is not magic film; it is an oxygen exchange equation. Delicate baby leaf and herbs can easily consume 10–30 ml O2/kg·h at 0–5 °C. You have to balance:

- Film OTR (oxygen transmission rate, in ml/m²·day·atm).

- Pouch surface area.

- Pack weight per bag.

- Expected temperature profile in transit.

Common errors:

- Using low‑OTR film designed for whole lettuce heads on high‑respiration herbs → O2 crash and anaerobic packages.

- Overfilling bags → effective O2 per kg product drops; any small temperature rise pushes you into fermentation.

- Packing warm product → internal O2 collapses before the container is even cold.

The science on herb storage and MAP is well developed, and general best practices echo what is seen in herb export guidance globally: control temperature first, then fine‑tune gas ratios as discussed here.

2.4 Regulatory blind spots: SFA, MRLs, and South African export controls

Singapore’s SFA framework expects importers to be licensed and to comply with food safety and labeling rules, including for fresh produce, as laid out in their importer guidance. On top of that, pesticide residue limits are codified by product group and active ingredient, and can be stricter than Codex for certain crops, as outlined in SFA’s pesticide residue pages here.

South African growers must also work within domestic controls. The Department of Agriculture, Land Reform and Rural Development (DALRRD) oversees plant health, phytosanitary certification, and export approvals for plant products through its export frameworks. PPECB then acts as the independent quality and cold‑chain assurance body for perishable exports.

When farms do not integrate these requirements early into their production planning and chemical programs, they end up with hydroponic herbs that look beautiful but fail on paper.

3. How to fix it: a practical sea‑freight playbook

3.1 Step 1: Lock your SKUs and temperature strategy

Start with a simple, conservative matrix:

Group A – cold‑tolerant herbs and baby leaf (0–2 °C):

- Flat and curly parsley

- Coriander

- Chives and spring onions

- Dill

- Baby spinach, rocket, robust mixed baby leaf

Group B – warm‑sensitive basil (10–12 °C):

- Genovese basil

- Thai basil

- Other tropical basil cultivars

Do not mix Group A and Group B in the same reefer. In the early phases, many farms will choose to sea‑freight Group A and continue flying basil until the programme is mature.

3.2 Step 2: Define CA targets per group

Work with your shipping line or container provider to lock the controlled atmosphere profile:

Recommended CA for Group A (0–2 °C):

- O2: 2–5 %

- CO2: 3–8 % (stay on the lower side for sensitive baby leaf mixes)

Recommended CA for Group B basil (10–12 °C):

- O2: 5–10 %

- CO2: 3–5 %

Ask for continuous logging of O2/CO2 and temperature and for post‑voyage reports on every shipment.

3.3 Step 3: Design MAP for herbs & baby leaf

Think in terms of target in‑pack atmosphere after equilibrium is reached at the shipping temperature.

Typical in‑pack targets at 0–5 °C for herbs and baby leaf:

- O2: 5–10 %

- CO2: 5–15 % (depending on herb sensitivity)

To get there, coordinate with your film supplier and provide:

- Product type (e.g. parsley, coriander, baby spinach).

- Pack weight (e.g. 50 g, 100 g, 500 g foodservice bags).

- Expected temperature (0–2 °C for Group A, 10–12 °C for basil).

- Transit time plus buffer (e.g. 14 days sea + 3 days distribution).

Ask them to model film OTR (and CO2 transmission) to hit that in‑pack range. Verify it yourself with gas sampling on trial shipments.

Practical tips:

- Use micro‑perforation or high‑OTR films for high‑respiration items like coriander.

- Use smaller bag weights instead of overloading large pouches.

- Always pre‑cool product to within 1–2 °C of reefer setpoint before sealing bags.

3.4 Step 4: Nail pre‑cooling and humidity control

Hydroponic produce is often harvested with high turgor and thin cuticles. That is good for texture, but it makes humidity control critical.

Pre‑cooling SOP:

- Hydroponic harvest into shaded, food‑grade bins.

- Immediate vacuum or forced‑air cooling for Group A down to 0–2 °C.

- For basil, cool to 10–12 °C only; do not pre‑cool below 10 °C.

- Only pack and seal product once internal leaf temperature hits the target band.

Humidity management:

- Target 90–95 % RH inside the reefer.

- Use corrugated cartons with ventilation slots sized to balance air flow and moisture retention.

- Avoid bare plastic crates without liners; they encourage dehydration.

PPECB cold‑chain guidelines reinforce rapid pulldown and maintained setpoint from packhouse to vessel. Building your SOP to mirror PPECB’s expectations makes export approval smoother and claims less likely according to their export standards.

3.5 Step 5: Align hydroponic production with export specs

Good shipping starts at the rootzone. For herbs destined for 10–14‑day transit, adjust your hydroponic program for robustness, not just speed.

Nutrient program:

- Run EC at the lower end of your cultivar’s productive range to avoid soft, watery growth (for many herbs, 1.4–1.8 mS/cm is a solid export target in NFT/DWC).

- Keep pH tightly in 5.8–6.2; prevent swings that cause latent deficiencies and tip burn.

- Avoid late heavy nitrogen pushes that create overly lush tissue prone to breakdown.

Harvest maturity:

- Herbs: harvest slightly earlier than peak volume to improve structural strength.

- Baby leaf: maintain uniform leaf size; mixed maturity increases respiration variability inside bags.

Well‑tuned hydroponic systems, including DWC and NFT, can deliver this consistency at scale. Containerised hydroponic farms already supplying export markets show how tight environmental and nutrient control builds reliable output that is easier to ship as seen in container farming case studies.

3.6 Step 6: Build SFA and DALRRD compliance into the process

Do not bolt compliance onto the end of the chain. Build it into cropping plans and chemical choices.

On the South African (exporter) side:

- Register with DALRRD as an approved export facility where required.

- Confirm which phytosanitary requirements apply for herbs and leafy veg to Singapore.

- Integrate PPECB inspections into every shipment: temperature checks, carton and label verification, and official export documentation.

On the Singapore (importer) side:

- Ensure your customer holds a valid SFA license to import fruits and vegetables under Singapore regulations as described here.

- Align your pesticide program with SFA’s MRL list; avoid actives with no established MRL for herbs where possible.

- Maintain batch‑level traceability from hydroponic bed/tank to carton and pallet ID.

4. What to watch long‑term: metrics, trials, and iteration

4.1 Build a structured trial programme before full rollout

Do not send your entire basil block on the first sea trial. Start with:

- 1–2 pallets per SKU in a mixed container, clearly marked as trial lots.

- Parallel air‑freight shipments from the same harvest for quality benchmarking.

- Detailed arrival checks in Singapore: visual, firmness, aroma, decay incidence, gas sampling in MAP bags.

Repeat across seasons. Hydroponic environments are stable, but ambient loading conditions, vessel schedules, and Singapore weather will move your risk around.

4.2 Track the right cold‑chain and quality KPIs

Create a simple dashboard for every shipment:

- Pre‑load leaf temperature: random probe checks; aim for ±0.5 °C around target.

- Container discharge temperature: continuous logger data from door to door.

- In‑pack gas composition at arrival: O2 and CO2 in MAP bags from at least 10 random cartons per SKU.

- Claim rate: % of cartons rejected or discounted per container.

Use this data to refine:

- Film selection and perforation patterns.

- Pack weights per bag and carton venting patterns.

- CA setpoints and reefer loading patterns.

4.3 Link your hydroponic controls to export performance

For serious hydroponic exporters, your environmental logs are as important as your bill of lading. Track:

- pH and EC by batch and harvest date.

- Canopy temperature, light intensity, and VPD leading up to harvest.

- Any nutrient profile changes (for example, pre‑harvest potassium reductions or calcium tweaks).

When Singapore buyers report a shelf‑life issue, you want to correlate it back to root cause: a hot week in the greenhouse, a nutrient tweak, or a deviation from your cold‑chain SOP.

4.4 Stay aligned with policy shifts and market expectations

Singapore’s push to diversify food imports and rely on partners like South Africa is part of a long‑term food security strategy as noted in policy coverage. That creates an export window for hydroponic growers, but it also puts a spotlight on reliability, food safety, and traceability.

Keep an eye on:

- Updates to SFA’s import and MRL frameworks.

- Changes in DALRRD phytosanitary rules for herb exports.

- New PPECB protocols or inspection criteria for leafy vegetables and herbs.

Integrate those changes into your SOPs as hard rules, not suggestions.

4.5 Turning this into a repeatable export “machine”

The farms that will win in the South Africa → Singapore hydroponic herb lane are the ones that treat every step as a controllable variable: resin choice, MAP design, CA profile, NFT/DWC nutrient strategy, and documentation stack.

Once you have that dialled in, sea‑freight stops being a gamble and starts looking like what it should be: a predictable, data‑driven extension of your hydroponic system across the ocean.

As an Amazon Associate, I earn from qualifying purchases.